As an authorized Rust Check Dealer, we offer the best protection for the second largest expenditure most people will make - their vehicle. Rust Check has been time tested and proven for over 40 years and offers a lifetime, unlimited mileage, unlimited ownership warranty. Ask today for more details!

WHAT IS RUST CHECK?

- Rust Check is a light oil-based electrochemical liquid, formulated to penetrate into crevices and seams by capillary action (where light liquids are drawn into crevices, even upward against gravity.)

- Coat & Protect is a thicker version of Rust Check, with the same active ingredients. Its thickness gives it good wash and wear resistance.

- All Rust Check products are safe and environmentally responsible - the main ingredients in Rust Check products are highly refined (purified) mineral oils.

WHY YOU SHOULD APPLY RUST CHECK

- Vehicles are subjected to thousands of spot welds, as well as numerous bends and folds during production. These processes damage the pre-coated metal, allowing exposure to the corrosion process.

- Corrosive salt and damaging moisture penetrate unprotected inner panel seams, depositing corrosive contaminants that will destroy metal over time.

- The corrosion not only affects the appearance of your vehicle, but can also attack the joints and spot welds that hold your vehicle together, resulting in a structurally unsafe vehicle.

HOW RUST CHECK WORKS

- Eliminates moisture, creeps into seams and crevices, bonds to metal (the corrosion inhibitors form an absorbed, bonded layer on the metal surfaces.)

- This microscopic layer acts like a series of tiny umbrellas, shielding the surface from water molecules.

- Once inside the crevices and seams, Rust Check dispels moisture and keeps it from penetrating, thereby inhibiting the corrosion process.

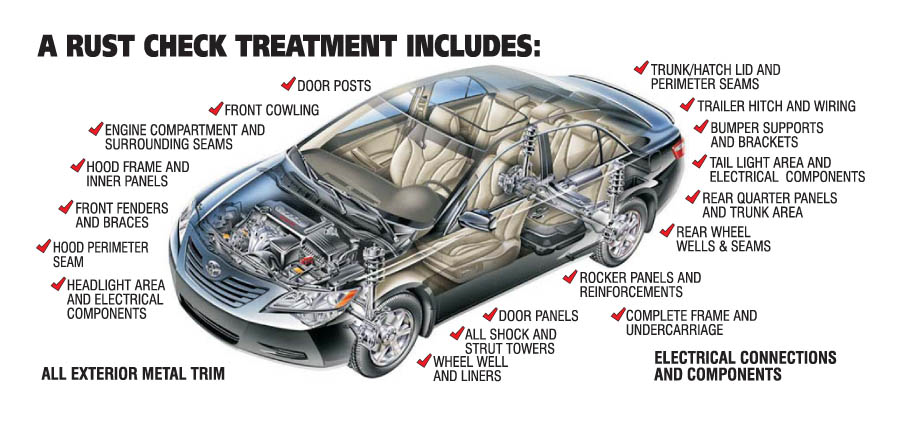

WHAT IS TREATED?

- Inside of doors, front and rear quarter panels, hood and trunk lid - treated to protect against rusting from the inside outward.

- Engine compartment, trunk, trim, and undercarriage also receive complete treatments.

THERE ARE TWO MAIN CATEGORIES OF AUTOMOBILE RUST PROTECTION – THOSE BASED ON OIL-BASED ELECTROCHEMICAL, AND THOSE BASED ON SEALANT.

WHAT IS THE DIFFERENCE BETWEEN RUST CHECK AND OTHER SEALANTS?

Rust Check - Oil-Based Electrochemical

- Non-drying, it remains mobile and won’t dry out, crack, or peel.

- Penetrates into welded seams and crevices and provides excellent protection for these corrosion-prone areas.

- Does not need shiny clean metal surfaces for application and good adhesion.

- Lubricates as it protects against corrosion.

- Does not contain smelly and toxic petroleum solvents.

- Reapplied every year to maintain a high on-going level of protection.

- Will not damage painted surfaces and can be easily cleaned off painted surfaces.

- The electrochemical compounds displace moisture, penetrate and treat crevices and seams and contain self-healing properties – while Rust Check will not reverse existing corrosion damage, it will slow the progression.

- The only two-product process on the market - this application process is designed to provide highly effective corrosion protection.

- The Coat & Protect provides the required protection for your vehicle undercarriage (it is a thicker version of Rust Check,) and eliminates dripping from the undercarriage, but does not harden.

- Rust Check can be applied at any time of year, in any type of weather.

- Lubricates power window and door lock mechanisms, prevents seizing of nuts, bolts, and fittings, and helps to eliminate squeaks and rattles ensuring hinges and cables operate smoothly.

Sealant Products

- Contain tars, waxes, or polymers.

- Usually applied on a permanent ‘one-time’ basis, sometimes with annual inspections or touch ups.

- Mainly sold by new car dealers.

- Sealants provide a barrier between the metal and the environment, restricting contact of water and oxygen with the metal.

- In order to be effective, the sealant coating must remain intact. Consequently, sealant coating relies on good adhesion to the surface onto which they are applied.

- Sealants are best applied to new metals or freshly and thoroughly cleaned and dried metals. If applied to corroded or wet surfaces, they may not adhere properly to the surface.

- Sealant products do not last forever; the typical warranty is 10 years.